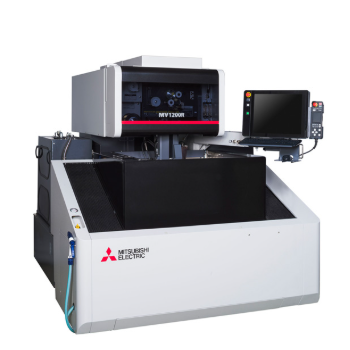

Our company KOVO Koudelka s.r.o. was established in 2007 and currently has 35 employees. We perform precision machining of steel, metal and plastics. Our machinery includes recent CNC milling machines and HURCO CNC lathes, the Mitsubishi CNC wire cutting machine, the ZEISS CMM 3D measuring centre and other useful production and measurement technology. We are a modern-thinking company that is trying to keep up with the times, and therefore, we invest a lot in our machinery, digitisation, automation and the satisfaction of our employees. In 2012, we had our quality management system certified according to ISO 9001 and 14001 and we have a strong system of continuous improvement. When we started, we only supplied to customers in the Czech Republic, but since 2009, exports to EU and non-EU countries have prevailed. Our production is 100% digitally controlled and ready for paperless production (APS / MES). We collect and evaluate data and measure the performance efficiency of our company. We quickly adapt to the needs of our customers; we always seek the best way for our joint business with a high focus on quality.